A few months ago the 3D printer (Ultimaker 2+ Extended) I bought arrived and I got started with printing out stuff right away.

In this article I will talk about the four worst things that happened while printing out various parts and how I fixed them.

At the end of this article is a short FAQ to give you some answers I wish I had when I started 3d printing.

1. Fixing a clogged nozzle

The atomic method is a process for clearing a clogged nozzle on a 3D printer. Here’s how it works:

- Heat the to the temperature of the filament you’re using.

- Use a piece of filament or a wire to push any debris or clogs out of the nozzle.

- Afterwards pull the piece of filament back out again and the nozzle should be clean again.

If the nozzle is still clogged after several attempts, try using a nozzle cleaning tool or remove the nozzle and clean it manually.

Atomic method guide by Ultimaker: https://ultimaker.com/en/resources/19510-how-to-apply-atomic-method

2. Stop material from getting stuck while printing

If material is getting stuck while you’re printing, it’s often caused by a clogged nozzle or incorrect temperature settings. Here are some steps you can take to stop material from getting stuck:

- Check the temperature settings: Make sure that the temperature of the hotend and the bed is set to the correct value for the material you’re using.

- Clean the nozzle: If the nozzle is clogged, use the atomic method or heat the nozzle and use a tweezer to remove the clog.

- Adjust the retraction settings: If the material is getting stuck due to retractions, try adjusting the retraction distance, speed, or temperature.

- Check the filament path: Make sure that the filament is being fed into the hotend properly. If it is not, try to feed it in manually.

- Check the bed level: If the bed is not level, the material may not be able to flow freely and may get stuck. Adjust the bed leveling to ensure that it is level.

If these steps don’t work, try reducing the printing speed, increasing the layer height, or adjusting the cooling fan settings. If the problem persists, you may need to replace the nozzle or the hotend.

3. Material not extruding anymore

If your material is not extruding anymore, there are several things that you can check:

- Make sure that your filament spool is not empty or that the filament is not tangled.

- Check if the filament is being fed into the hotend properly. If it is not, try to feed it in manually.

- Make sure that the hotend is hot enough. If it is not, increase the temperature until the filament starts to flow again.

- Check if the nozzle is clogged. If it is, try to clear the clog using the atomic method or by heating the nozzle and using a tweezer to remove the clog.

- If none of these solutions work, you may need to replace the nozzle or the hotend.

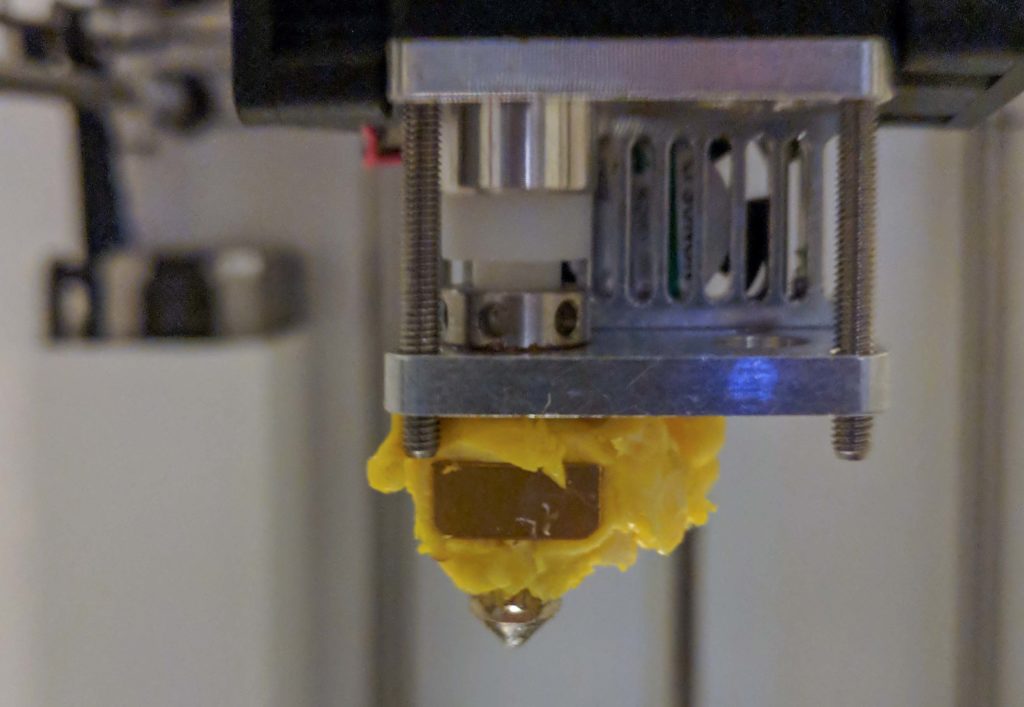

4. Fixing a leaking or caked nozzle

If your nozzle is leaking material the most likely cause is that the nozzle isn’t screwed in enough.

When your nozzle looks like this the best way to get rid of the material stuck to the nozzle is to heat the nozzle up to 180 degrees Celcius and the use a tweezer to remove the material. (http://support.3dverkstan.se/article/23-a-visual-ultimaker-troubleshooting-guide#caked-nozzle)

After removing the material keep the nozzle heated up and tighten it with the torque wrench. (In more detail: https://ultimaker.com/en/resources/18020-installing-the-nozzle)

If the Olsson block or the nozzle breaks because of the leaking filament you can just order a replacement part and replace it yourself easily.

FAQ

What is slicing?

Slicing is the process of converting a 3d model into a file that the 3d printer can actually understand and print out. For example converting a .stl file into a .gcode file.

What applications can you use for slicing? / What are the benefits of the different applications?

I’m using Cura (https://ultimaker.com/en/products/cura-software) which was developed by Ultimaker, but also works with a lot of other printers.

What should I use to model my own designs?

For simple models I use tinkercad.com. As far I haven’t created more complicated models and it’s a great and easy tool to get started.

What can I do if I have a stuck screw that I can’t turn anymore with my screwdriver?

Use the jagged part of a plier to turn the stuck screw.